3D CELL CULTURE APPLICATIONS

Versatile Bioreactors for a Wide Range of Sensitive Cell Types

Explore our proof of concept showcasing scalable, efficient, and versatile cell growth—demonstrating the power of our bioreactor technology in advancing therapeutic and pharmaceutical research.

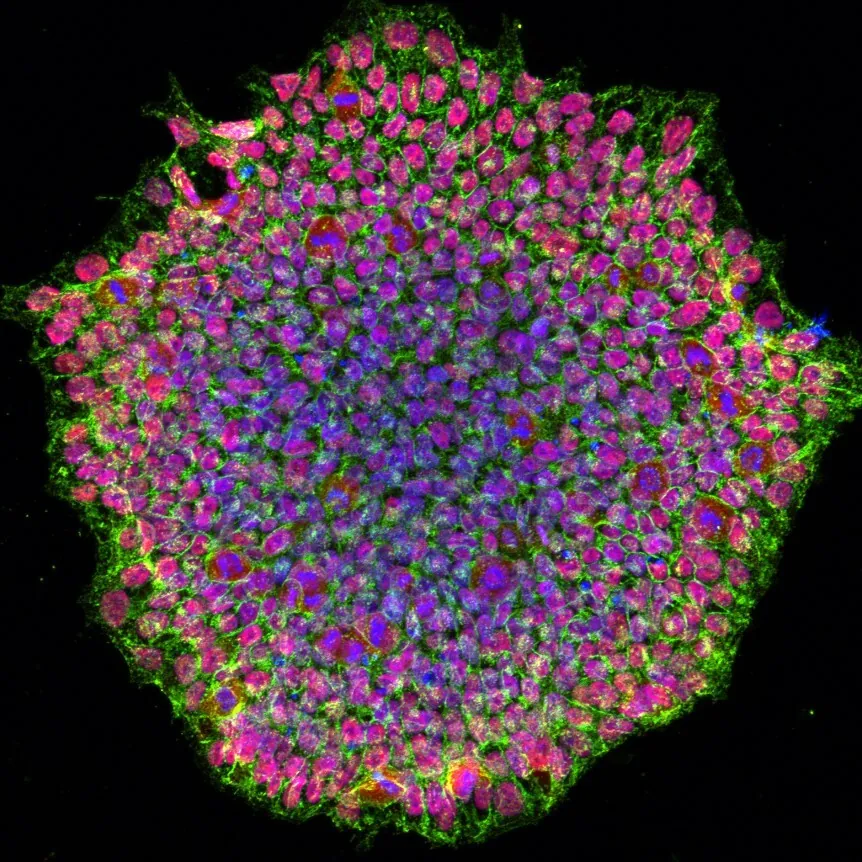

Stem Cells

UNLOCKING SCALABLE STEM CELL EXPANSION FOR THERAPEUTIC USE

Induced Pluripotent Stem cells (iPSCs) are genetically reprogrammed cells capable of dividing in culture with unlimited self–renewal.

The emergence of these cells represents an opportunity to create a potentially unlimited cell source for differentiation into specialized cell types, ideal for applications in gene and cell therapy, regenerative medicine, and personalized treatments but also cultivated meat.

Our system allows for homogeneous expansion of iPSCs which can be grown in 3D aggregates with preserved biomarkers and pluripotency, offering an efficient alternative to traditional adherent cultures.

This enables more consistent results for disease modeling, drug screening, and future therapeutic applications and making affordable the emergent cultivated meat market.

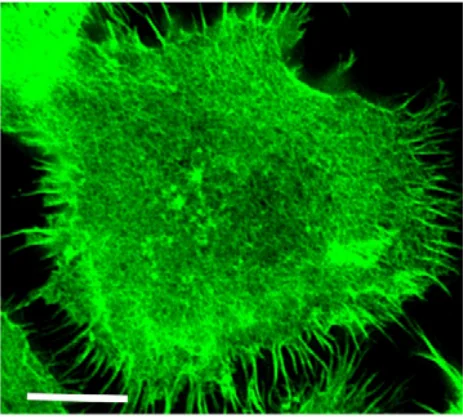

Immune Cells

NK AND T CELLS FOR IMMUNOTHERAPIES

Natural killer (NK) cells have recently shown renewed promise as therapeutic cells for use in treating hematologic cancer indications. Their excellent immune tolerance makes them great candidates for allogeneic therapies, requiring large scale manufacturing.

Successful scale–up of NK cells critically depends on a manufacturing process sustaining their expansion while preserving their cytotoxic functionality.

Our low–shear bioreactors support the expansion of fragile immune cells, including NK and T cells, essential for cancer immunotherapy and infectious disease treatment. The controlled environment enhances cell viability, activation, and scalability.

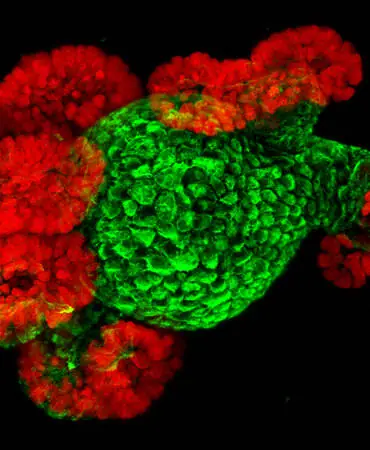

Organoids

BRIDGING RESEARCH AND REAL BIOLOGY

Organoids represent a breakthrough in biomedical research and biotechnology. By mimicking the 3D structure and function of real human tissues, they offer a powerful model for studying disease mechanisms, testing drugs, and developing personalized therapies. At Cellura, we focus on organoid technologies to bridge the gap between traditional cell cultures and complex human biology accelerating innovation in regenerative medicine, drug discovery, and beyond.

Our bioreactors are specifically designed to support the growth of organoids, which require gentle suspension to achieve proper three-dimensional development. By maintaining optimal mixing conditions and minimizing shear stress, our systems create an ideal environment for organoid culture—ensuring uniform nutrient distribution, enhanced viability, and scalable growth.

Our initial results using functional thyroid gland organoids clearly demonstrate the superiority of our bioreactor systems. By enabling consistent suspension and 3D growth, our technology supports the formation of structurally and functionally mature organoids—validating its potential for complex tissue engineering and therapeutic applications.

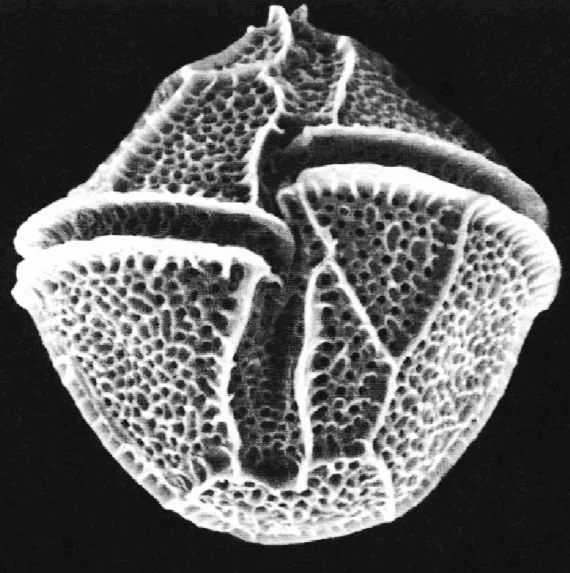

Microalgae

GIVE ACCESS TO A NEW SOURCE OF MOLECULES

Microalgae like dinoflagellates can be cultured at scale using our platform, opening up opportunities in nutraceuticals, bioactives, and functional food ingredients.

Dinoflagellates are highly sensitive marine microalgae capable of producing rare and valuable biomolecules. However, their industrial use has long been limited by the difficulty of culturing them without damaging their fragile structures.

Thanks to our bioreactor platform, Cellura achieved exceptional cultivation performance with these challenging cells:

- 1 billons cells produced in just 6 days

- Viability maintained at over 95%, even under continuous dynamic mixing

- Significantly higher growth rate than in standard static cultures

- Viability maintained at over 95%, even under continuous dynamic mixing

These results demonstrate the superior performance of Cellura’s low-shear system for cultivating fragile, shear sensitive microorganisms — paving the way for industrial-scale production of high value compounds from dinoflagellates, such as marine toxins, antioxidants, carotenoids, and Polyunsaturated fatty acids.

This application highlights Cellura’s potential in marine biotechnology, with direct implications for pharmaceuticals, functional nutrition, and sustainable biomanufacturing.