Technology

The major issue in conventional 3D culture of sensitive cells is the presence of strong shear forces induced by the mixing system (wheel, helix, turbine or bubbles).

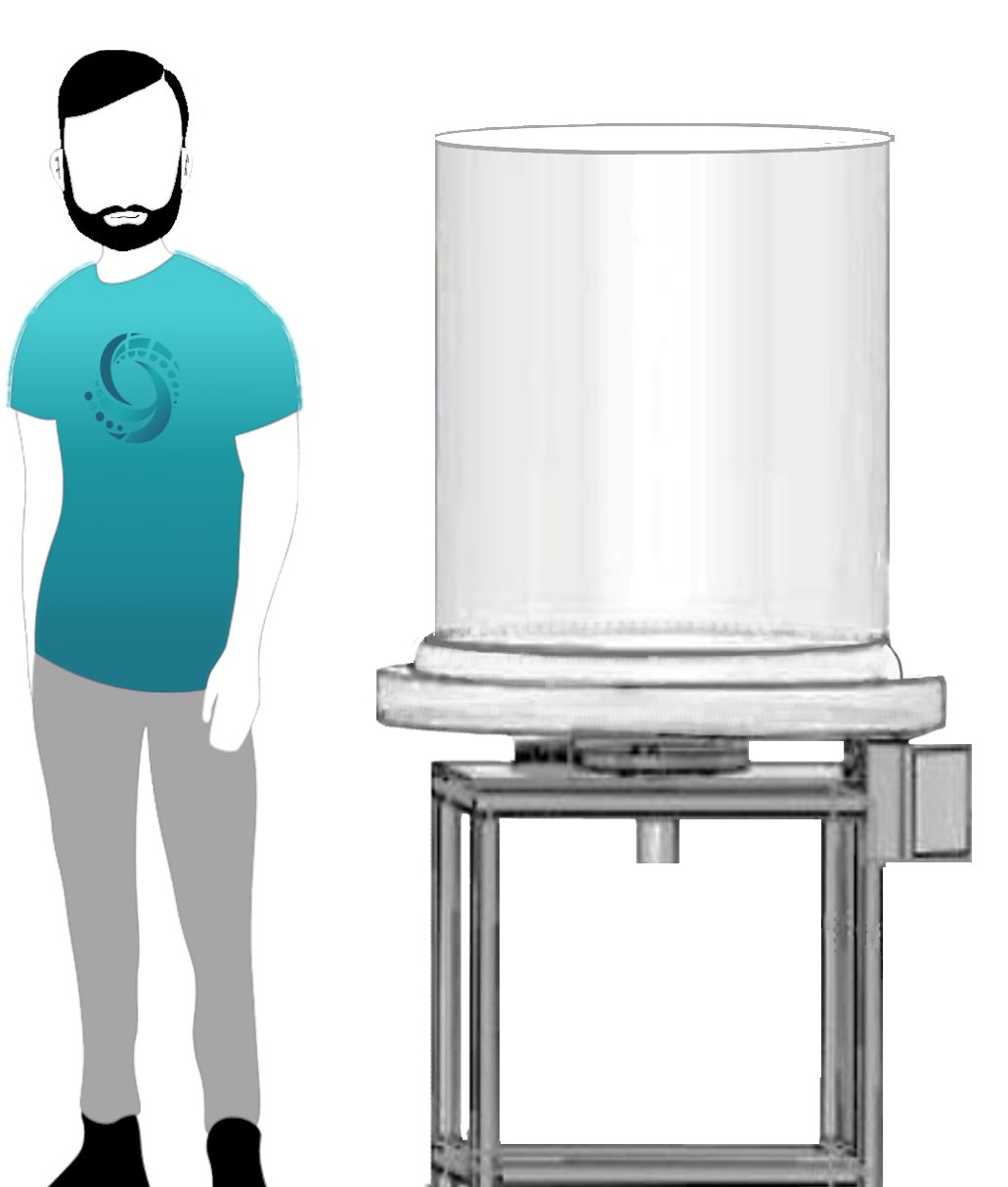

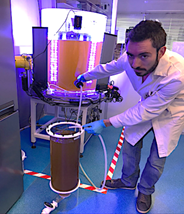

Our innovating bioreactor permit to get a homogeneous mixing of nutrients and gases with a minimum shear.

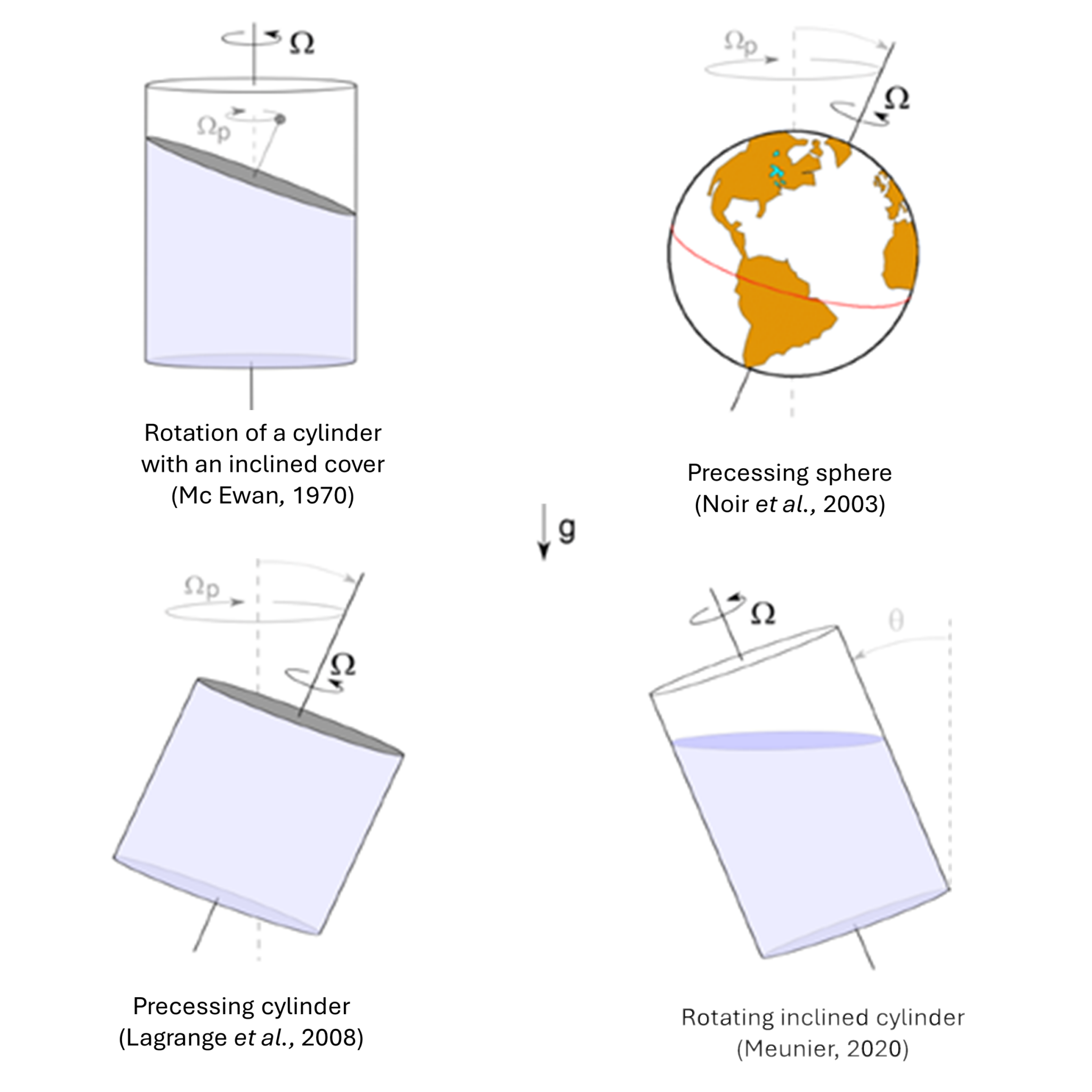

Fluids in a precessing cylinder

Turbulent mixing

Shearing forces inside the cylinder

Homogeneous mixing

Benefits

Cost effective:

Conventional bioreactors use detrimental stirrer tools which complexify the biomanufacturing process, generate foam, and prevent the scale up.

In our scalable bioreactors, you have a full control on the shear within a very simple biomanufacturing process, preserving for example the self-renewal capacities of pluripotent stem cells.

This translates in a very cost-effective process whatever the scale, from R&D to clinical needs.

Scalability:

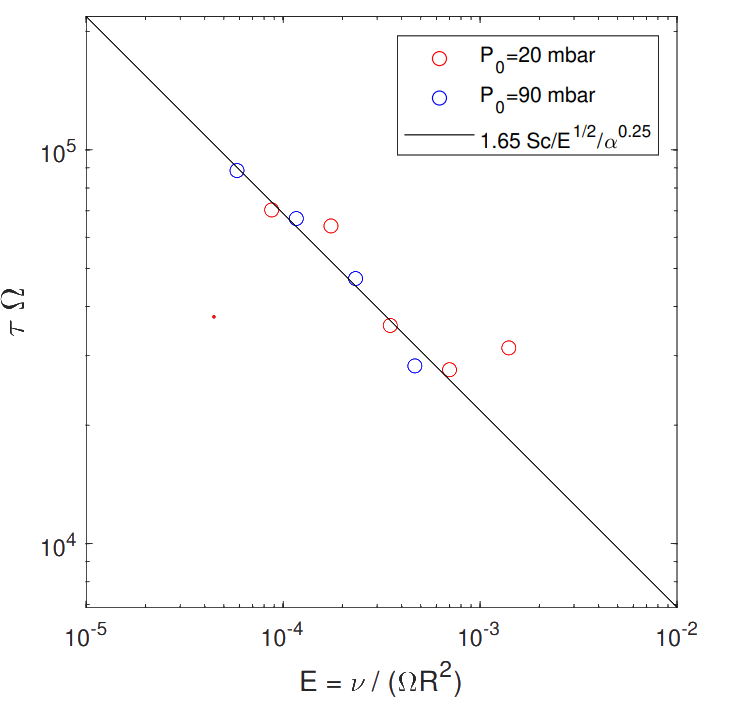

In conventional bioreactors, the size of the stirring device (turbine, wheel or helix) must increase with the size of the container.

The shear stress thus increases strongly with the volume (red curve).

Maximal mass transfer:

Finally, we have measured the flux of gas such as oxygen or carbon dioxyde that can penetrate or exit at the free surface.

This flux is larger by 2 orders of magnitude compared to the case of a static cylinder.

This is essential for an efficient bioreactor. It means that the number of living cells in the bioreactor can be increased by 2 orders of magnitude.

Cell models

Our technology was successfully used on several cell models from human cell to microalgae.

Stem cells

Induced Pluripotent Stem cells (iPSc) are genetically reprogrammed cells capable of dividing in culture with unlimited self-renewal. The emergence of these cells represents an opportunity to create a potentially unlimited cell source for differentiation into specialized cell types.

However, their amplification remains delicate. Current 3D technologies with stirrer tools can easily lead to premature cell differentiation, or damage them with excessive shearing forces, reducing yields and leading to high costs.

In our bioreactor, we could amplify iPSc during 2 weeks without passage. We started with a 10^5 cell/ml up to 10^7 cell/ml.

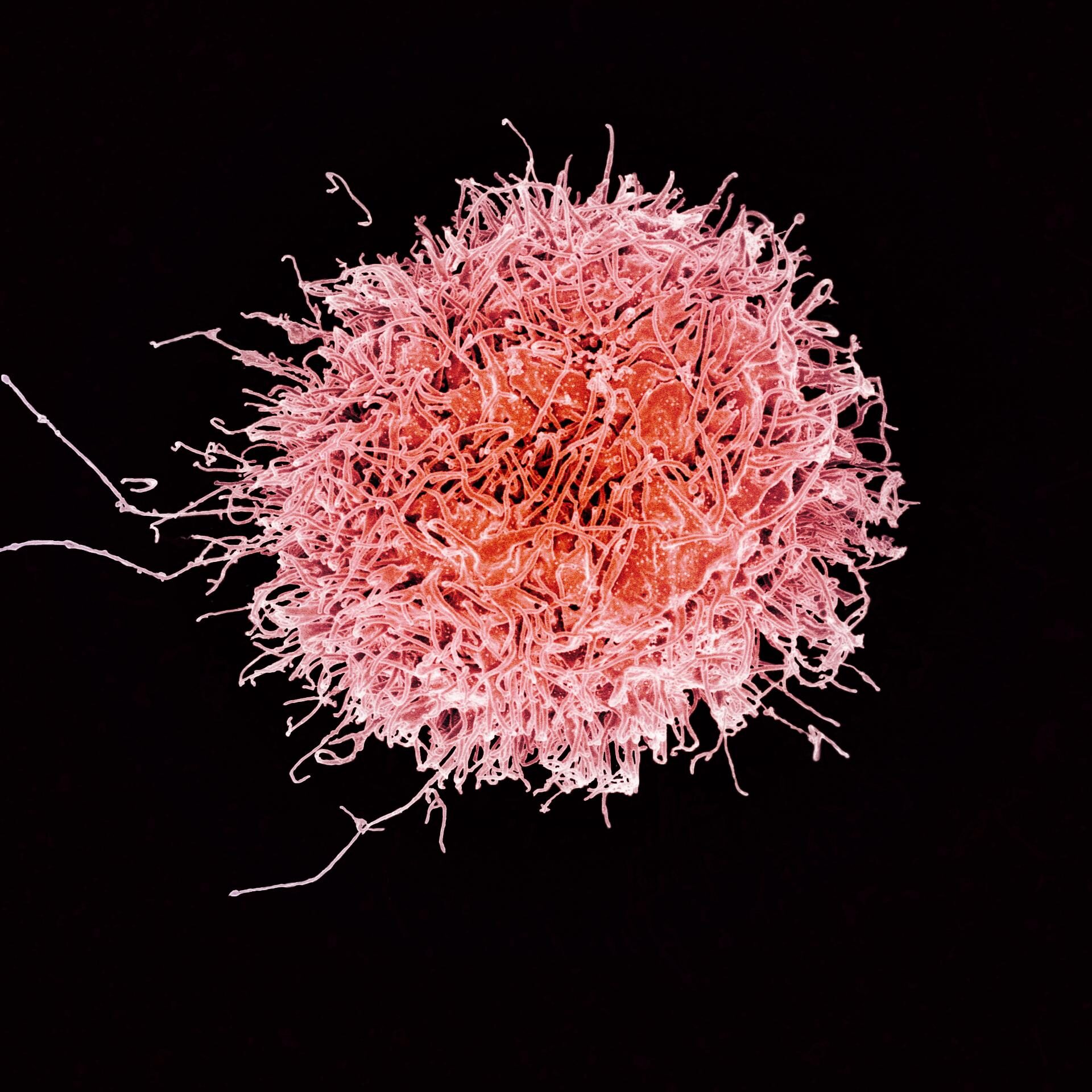

Natural Killer

Natural killer (NK) cells have recently shown renewed promise as therapeutic cells for use in treating hematologic cancer indications. Their excellent immune tolerance make them great candidates for allogeneic therapies, requiring large scale manufacturing.

Successful scale-up of NK cells critically depends on a manufacturing process sustaining their expansion while preserving their cytotoxic functionality.

Dinoflagellates

Dinoflagellates are a family of microalgae which is particularity shear-sensitive. They are really promising in drug development (Detournay et al., palytoxine, 2023) because they produce potent bioactive small molecules showing high affinity for ion channels, the most important pharmaceutical targets.

However, no technology exists to cultivate dinoflagellates at high yield (only 2D culture is possible) leading to high production costs and as a consequence pure molecule price on the market ranging from 10 to 90 k€/mg.

Thanks to our bioreactors (1- 200L), we have proved that it is possible to cultivate these shear-sensitive microalgae in 3D conditions at high yield level, making the biomanufacturing process affordable and scalable.

These results pave the way to the industrial production of microalgae of interest for pharmaceutical purposes in a wide range of applications (Lefranc et al., 2023)

These molecules were demonstrated to have a high tropism for ion channels the second therapeutic target. However, no technology exists to cultivate dinoflagellates at high yield.

Only 2D culture is possible leading to molecule of interest with prices about 30k€/mg and more.

With our technology, we proved that it is possible to cultivate these shear-sensitive microalgae at high yield and good reliability.

These results indicate that is possible to produce high potential molecules from dinoflagellates at affordable price, which could address the lack of new bioactive molecules for drug discovery.

Publications & Patents

Two patent has been filed on this bioreactor : The first (WO2017149034A1) and the second (FR3117505A1), thus we decided to share it with scientific community.

Our technology came from seven years of development leading to numerous publications and a PhD in physics and computational fluid dynamics, mainly managed by Patrice Meunier (IRPHE, Aix Marseille Université) Learn more.